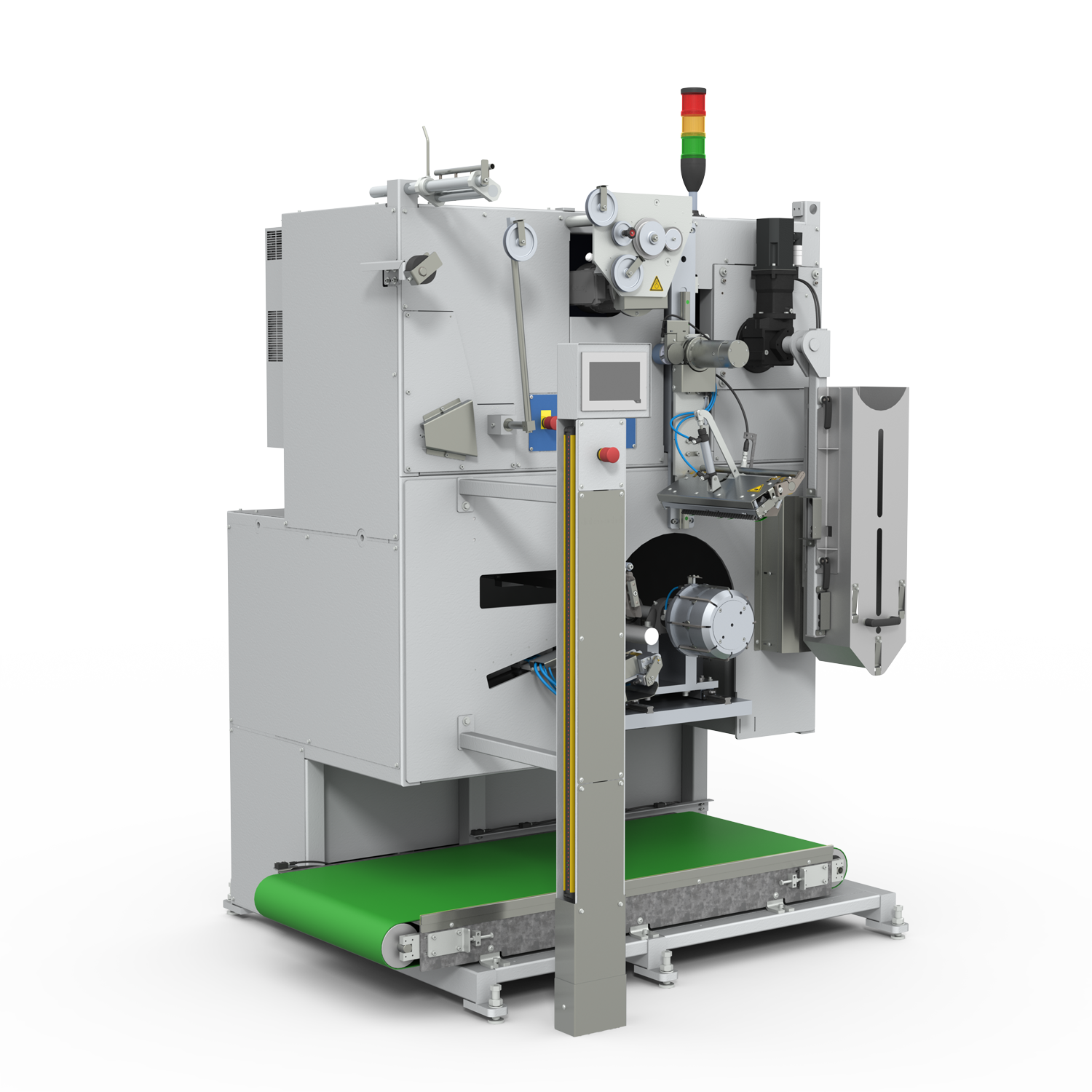

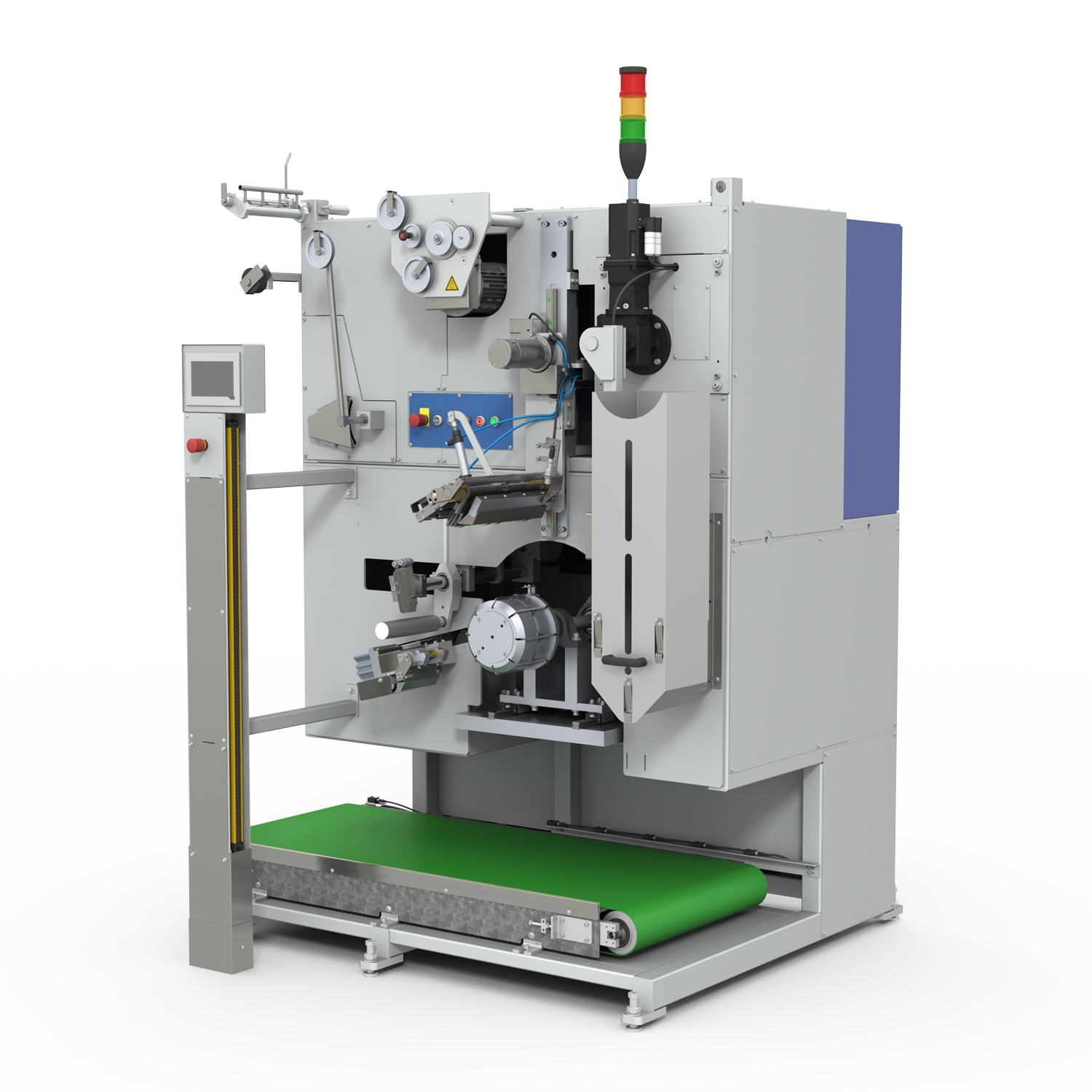

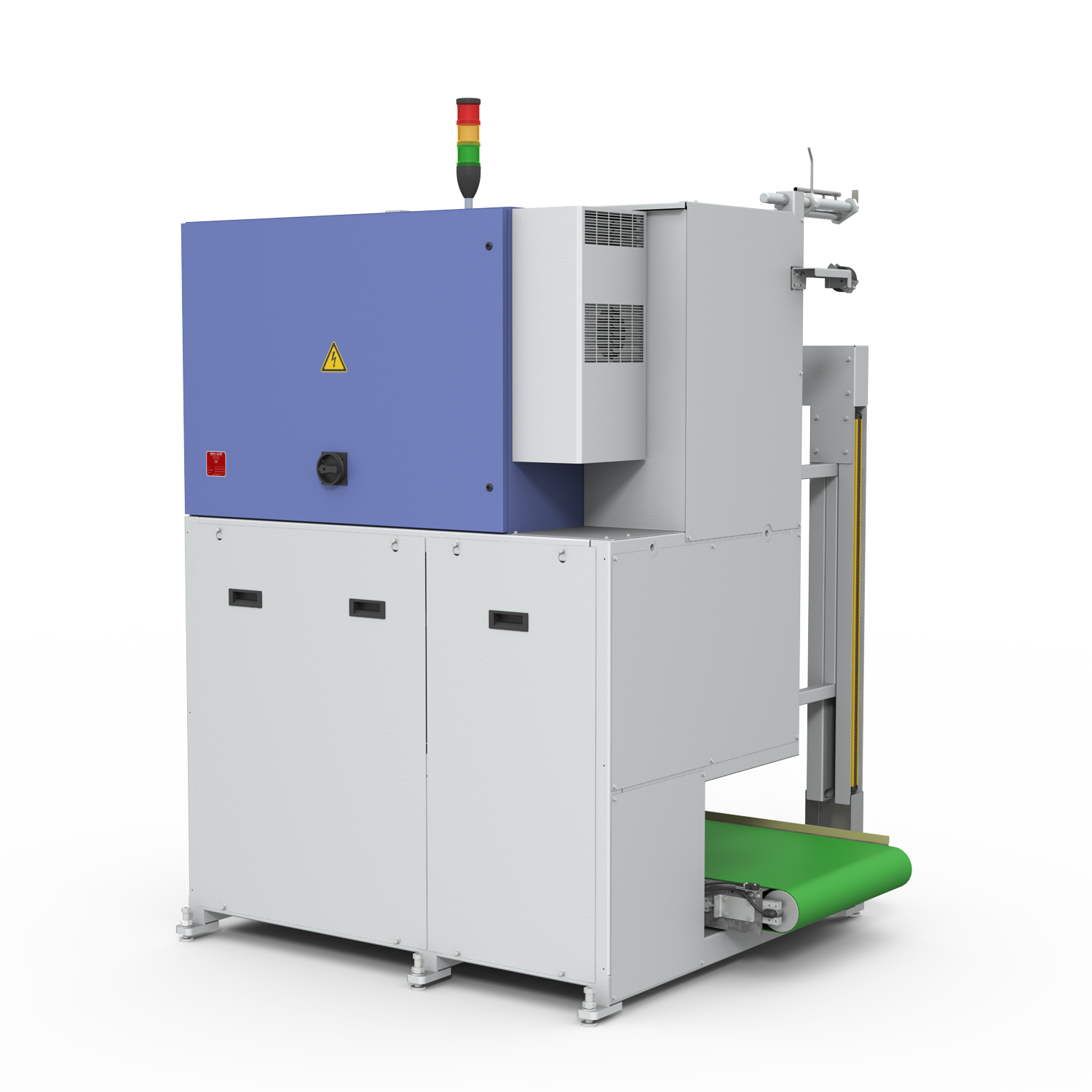

Automated strap winders from the extruder

The strap winders of the VBW A series are used for winding straps in parallel directly from the extruder.

The systems work independently once the material has been applied manually. They can be integrated into a fully automated overall production plant. They wind PP straps with widths of 4 to 25 mm depending on configuration. Networking joins the individual winding positions together into production lines.

Once a winding package has reached the desired circumference, it is wrapped with film by the integrated winder and removed from the line by the integrated transport system. A new winding tube is fed from the magazine at the same time and the next package is wound fully automatically.

The machines were developed for continuous operation. The compact design permits use even in confined spaces.