The right solution for any material: with Dietze+Schell systems and plants

Manual or automatic bobbin swap

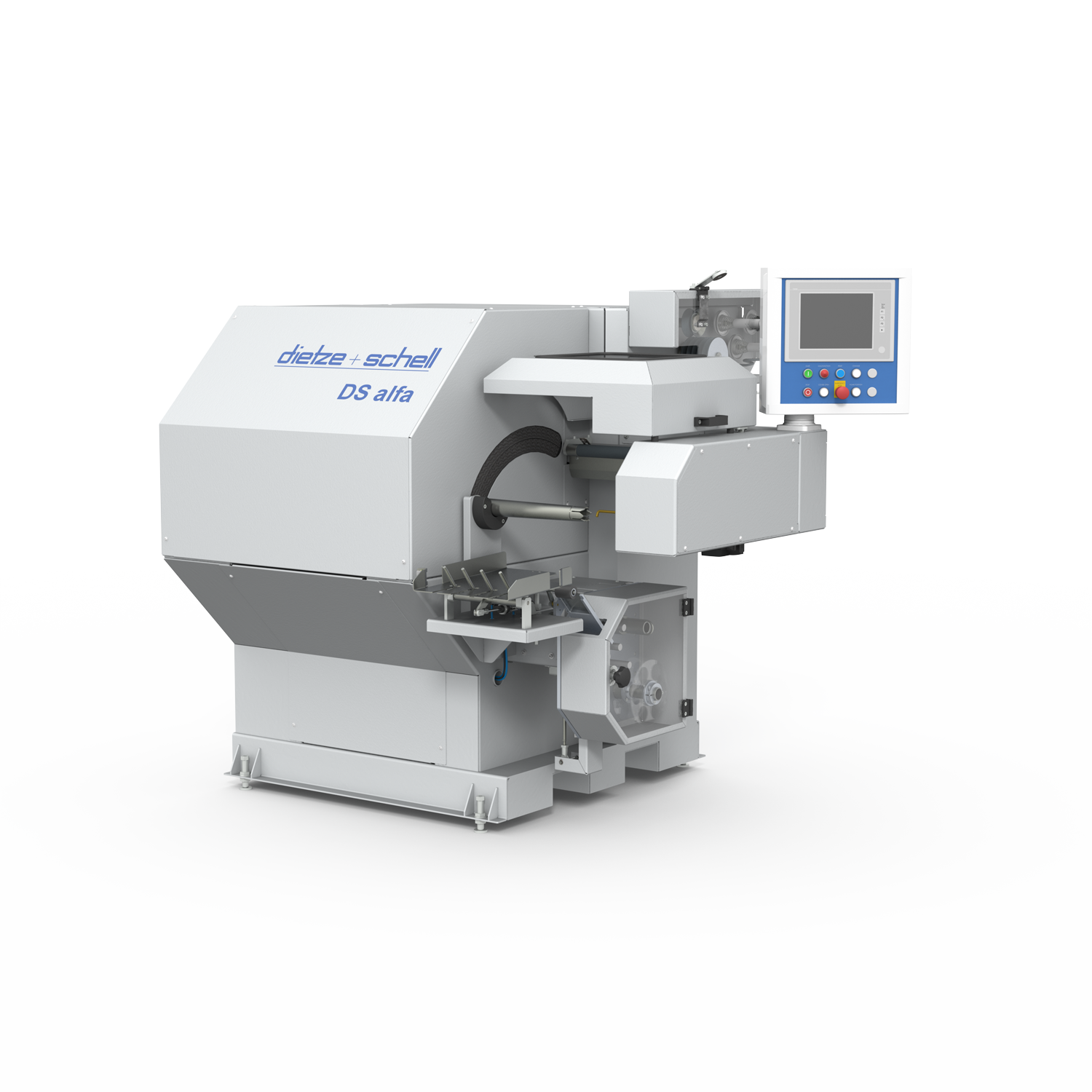

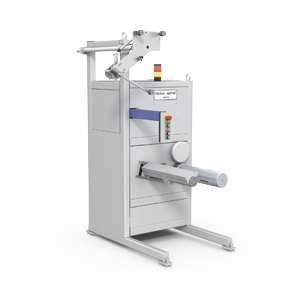

DS Alfa specialises in the manufacture of technical yarns and baler twines. Dietze+Schell offers several versions of these. In the stand-alone version with manual operation, an operator handles the empty sleeves and full bobbins. The DS Alfa can also be integrated into a transport system for fully automatic packaging of the finished packs. Automatic bobbin swap is possible when the thread is not moving.

Central yet individual control

The precision cross winder is designed for bobbins weighing up to 15 kilograms and a diameter of 320 millimetres. The maximum rewinding speed is 600 meters per minute. DS Alfa is often combined with 20 or even more systems. They are controlled centrally via a terminal that customises parameters for each machine.