The right solution for any material: with Dietze+Schell systems and plants

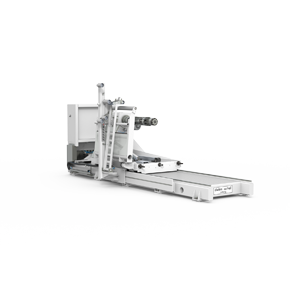

The take-up parallel winder SW 500 winds material lanes with widths of up to 30 mm and more. These include single or double-sided glue-coated or uncoated films, silicone papers, non-wovens, foams, cork and hook-and-loop tapes.

A dancer arm system ensures that the material is wound at a constant tension and speed. The belt tension is adjusted via an electronic pressure control on a central operating terminal. Unlike the SW 4, the SW 500 has a moving spindle (bobbin). It reduces material deformation along the bobbin edges. Larger strap widths and more sensitive materials can be wound this way.

Many operators combine the take-up parallel winder with a cutting system.