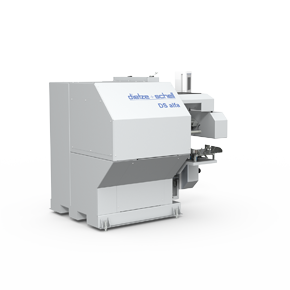

The right solution for any material: with Dietze+Schell systems and plants

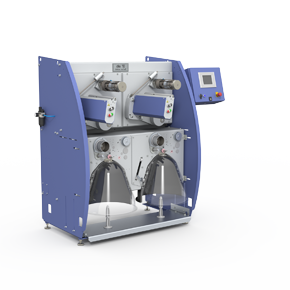

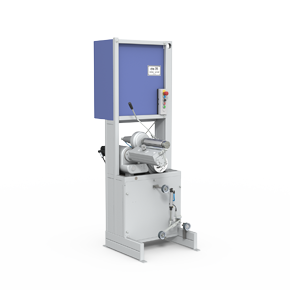

EW machines are some of the heavy-weights among precision cross winders. They wind packages weighing up to 1,500 kg and with diameters of 500, 800, 1,000 or 1,500 mm, depending on the machine version. They find their use in production of acrylic fibres and raffia yarns (e.g. baler twines). The manufacturers initially wind large bobbins for stock-keeping and then customise smaller units from these based on to customer orders.

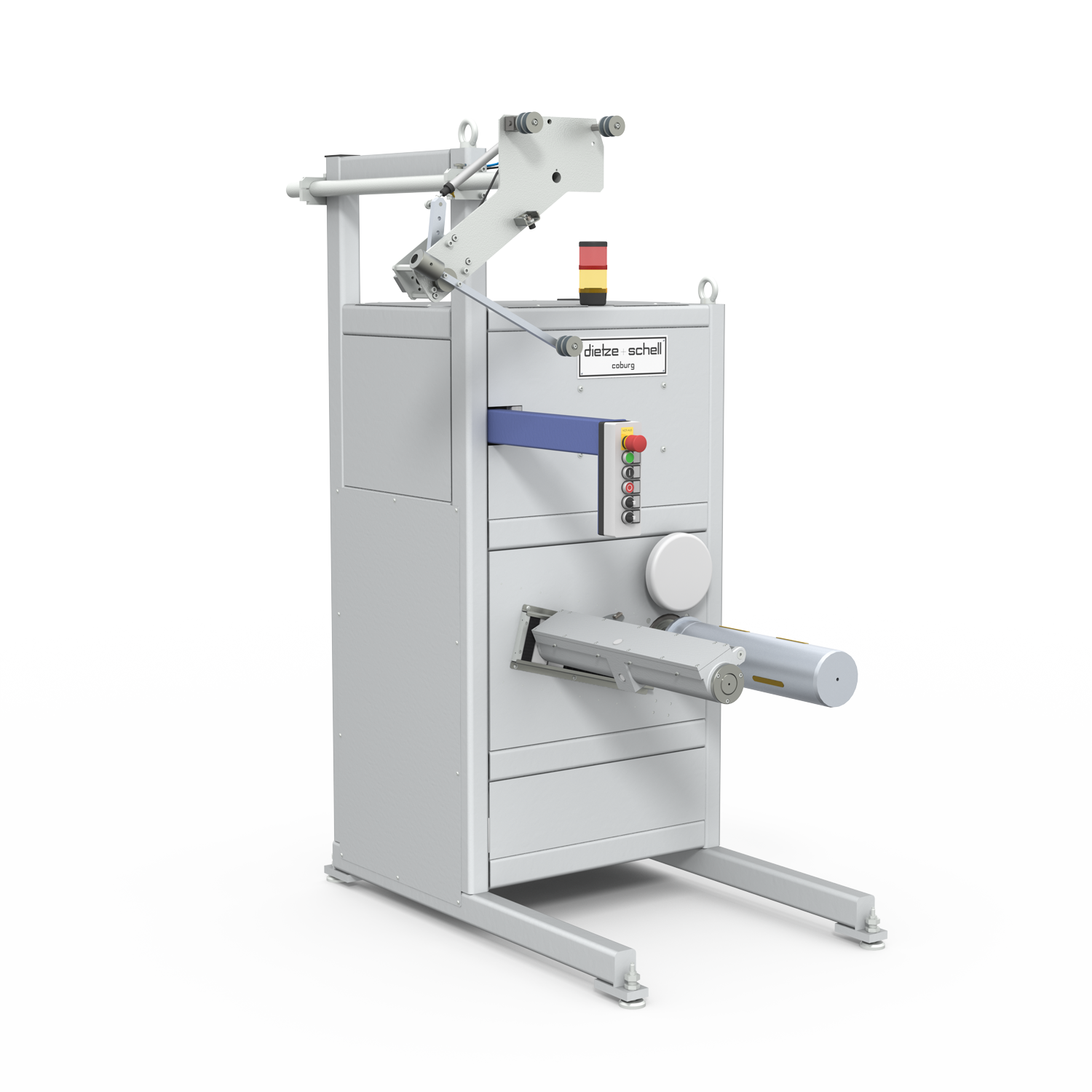

The individual winding positions can be combined into production lines by networking the individual machines. The compact design permits use even in confined spaces. The machines were developed for continuous operation.