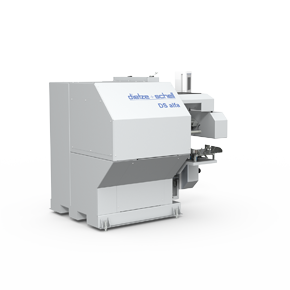

The right solution for any material: with Dietze+Schell systems and plants

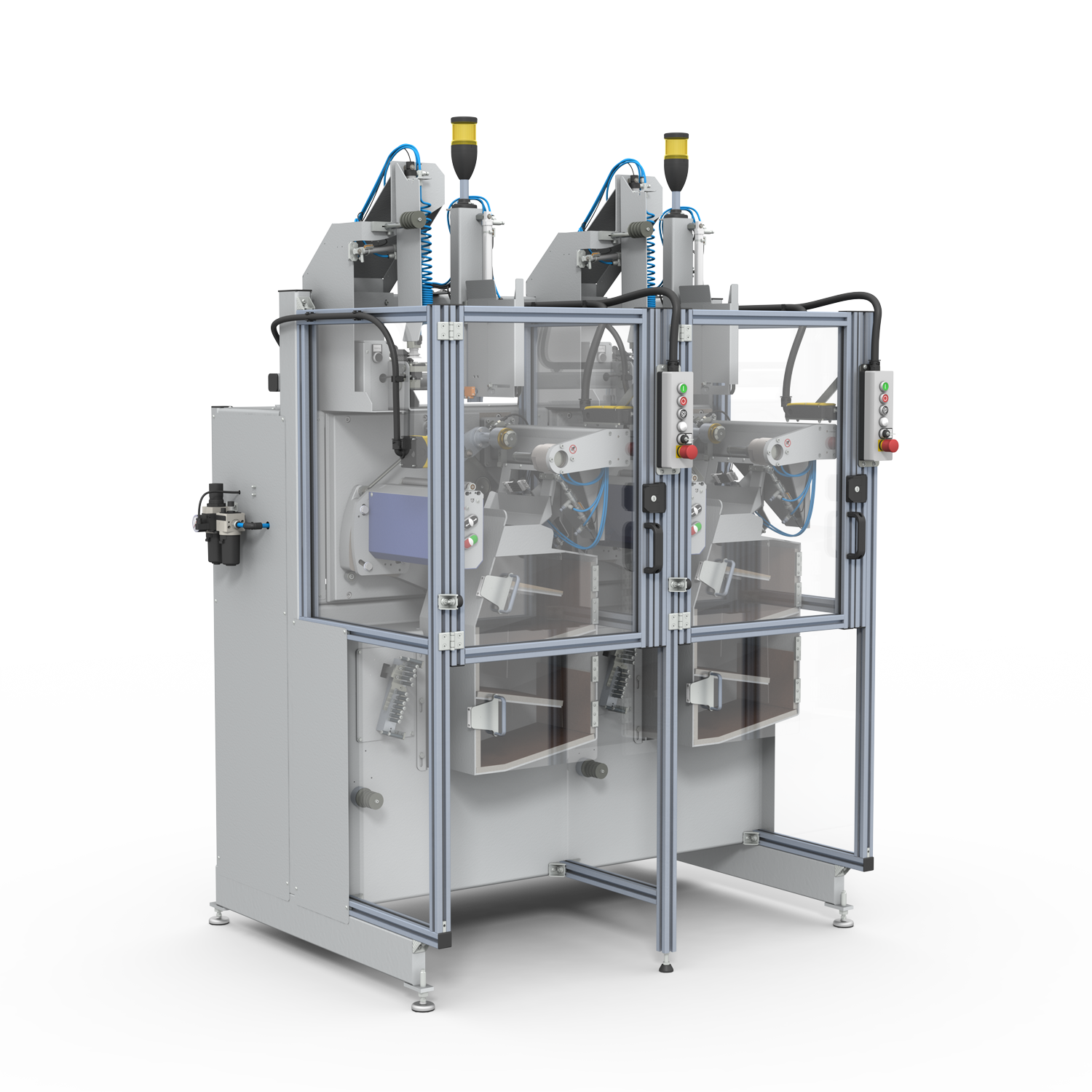

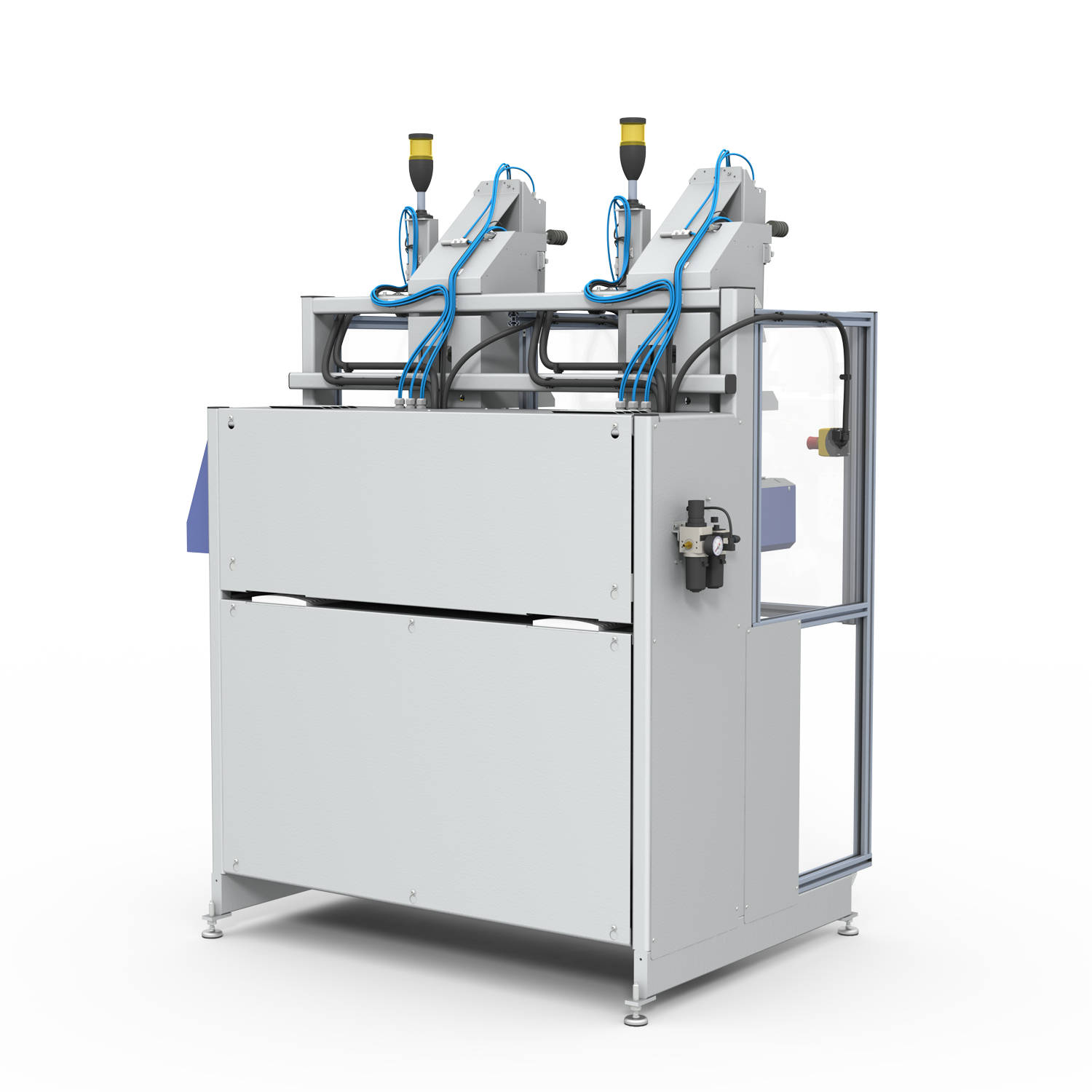

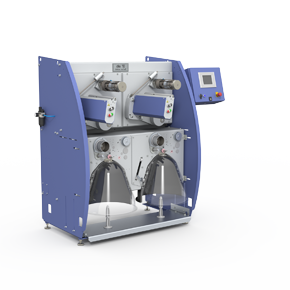

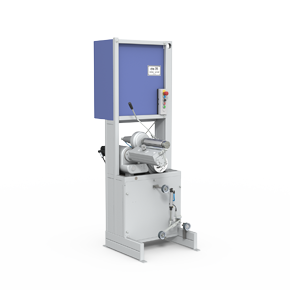

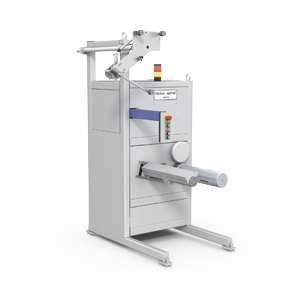

The DS10A is a precision cross-winder for technical yarns. The rewinding machine is technically based on the DS10 with electronic control.

The DS10A was developed for discontinuous rewinding processes in serial production. Frequent bobbin swaps are needed due to the compact and rather small-formatted packages. Swaps often take place up to 30 times per hour. The machine swaps on its own. It sends the full bobbins to a storage compartment and removes an empty sleeve from the magazine to continue the process.

The system design is targeted at letting a single employee operate multiple machines at the same time. The employee only needs to top up empty sleeves and remove the full bobbins from the storage compartment.