The right solution for any material: with Dietze+Schell systems and plants

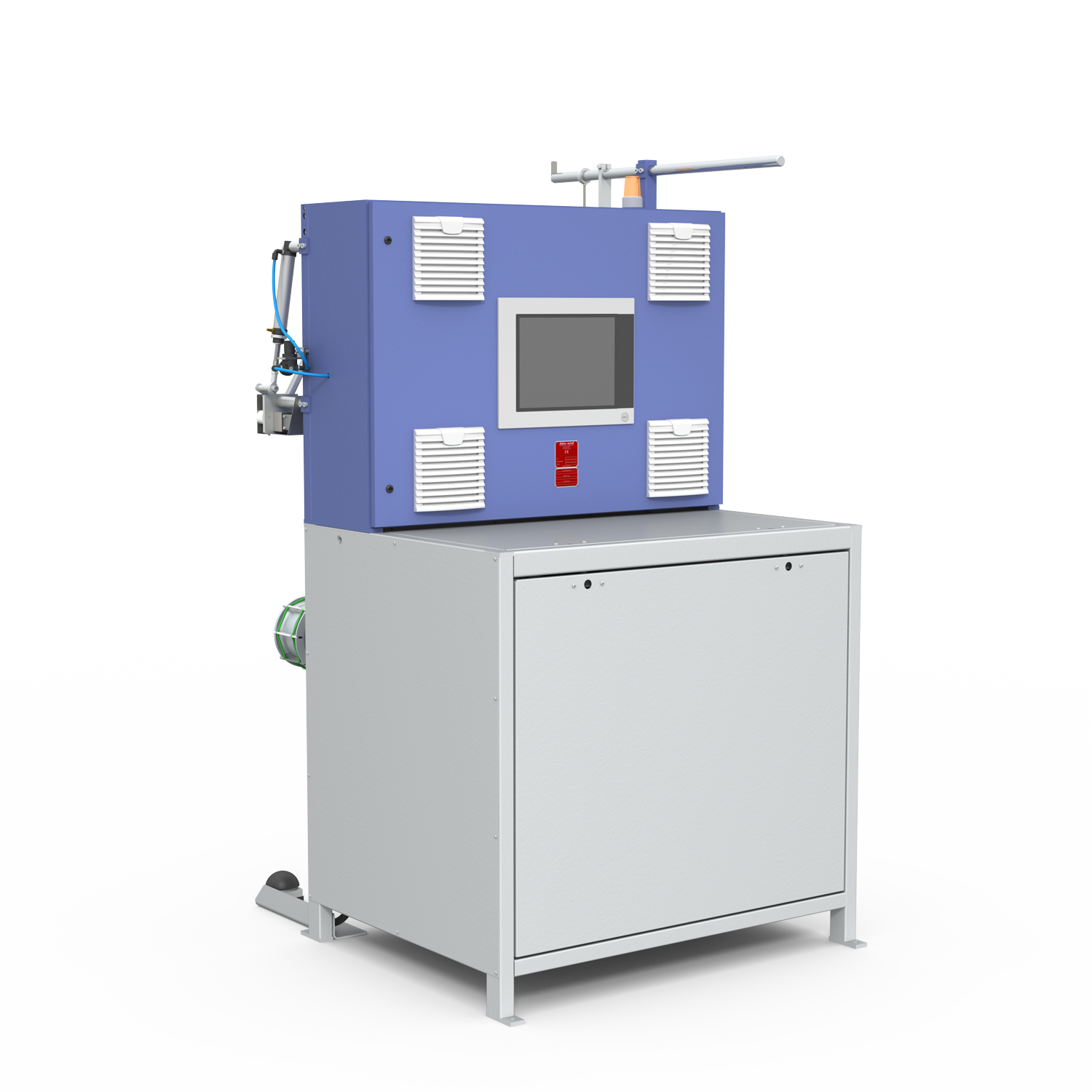

The strap winder family is used for winding straps in parallel directly from the extruder. These machines come with one or two winding mandrels. Versions with two bobbin mandrels permit particularly fast manual bobbin swap.

Networking of individual machines joins the winding positions together into production lines. The compact design permits use even in confined spaces.

The machines were designed for continuous operation. They wind 4 to 32 mm wide PP or PET straps based on specific winding programmes. Dietze+Schell customises them based on specific customer specifications.