From the extruder to the bobbin

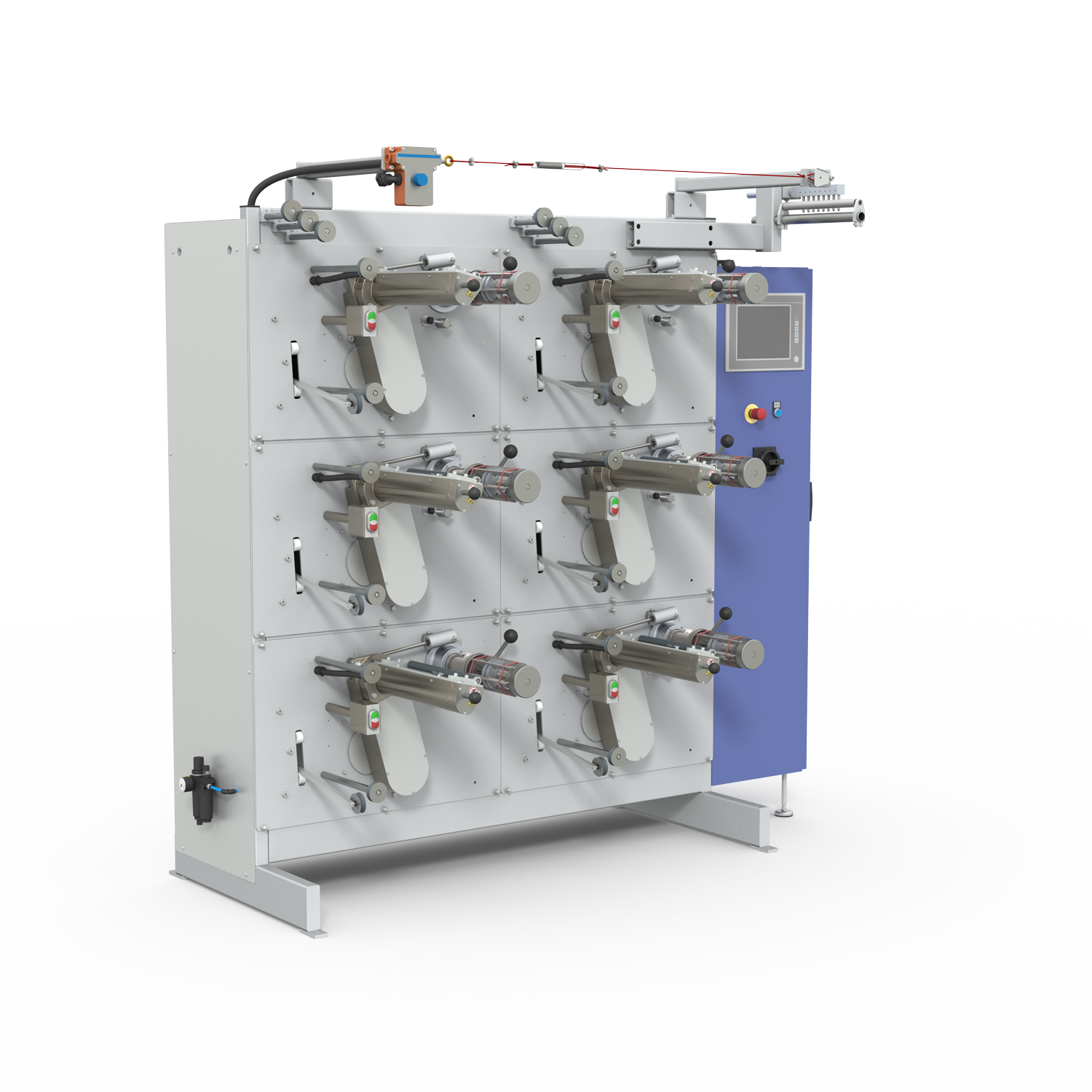

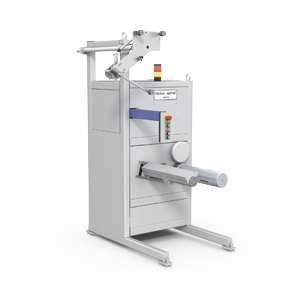

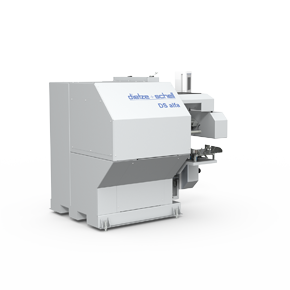

Dietze+Schell has developed the DS 10E TU and DS 10M TU take-up machines for yarns continuously supplied by production or finishing. Up to six bobbins can be mounted on the machine frame in this compact and economically sized design.

Electronically...

The Precision Cross Winder DS 10E-TU has an electronic control. It was developed for companies subject to constantly varying requirements to the winding process. This applies in particular to yarn manufacturers that need to adjust to the individual customer product requirements at short intervals. Manufacturers with a broad product range also benefit from the diverse options.

The machine electronically adjusts its winding width, thread tension, contact pressure, speed and other parameters.

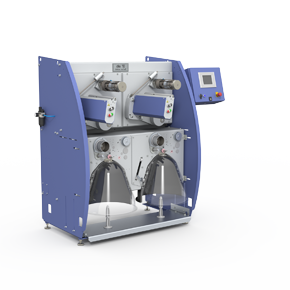

... or mechanically controlled

The mechanical version, the DS 10M-TU, has no electronic control for the crossing. This reduces costs. The setting is made via change gears. This type of machine is mainly used where the lines rewind the same product for months and changes are rare.

DS 10M TU and DS 10M TU are precision cross winders.