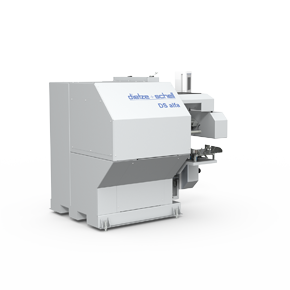

The right solution for any material: with Dietze+Schell systems and plants

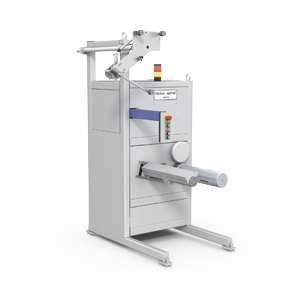

Electronic control: When parameters change frequently

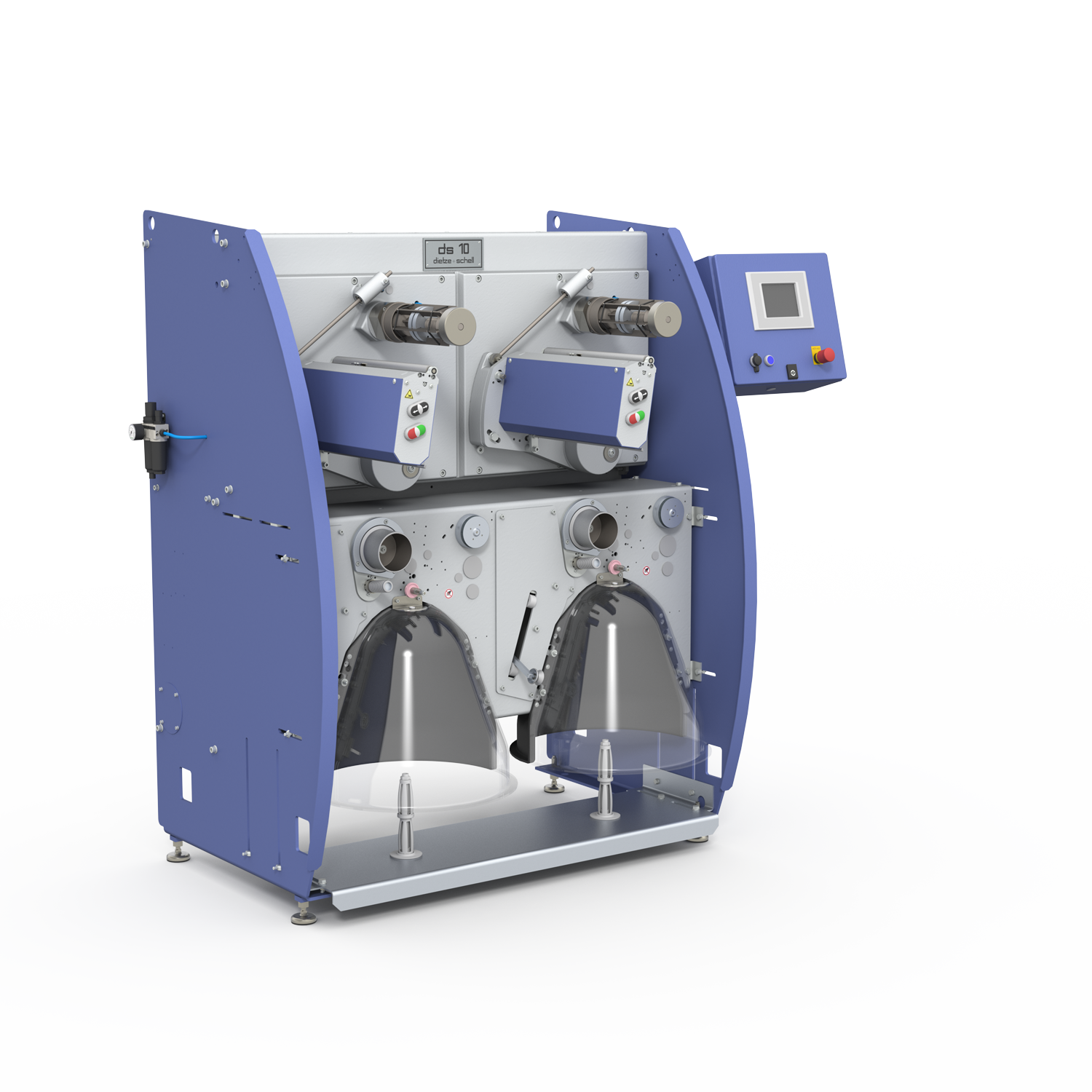

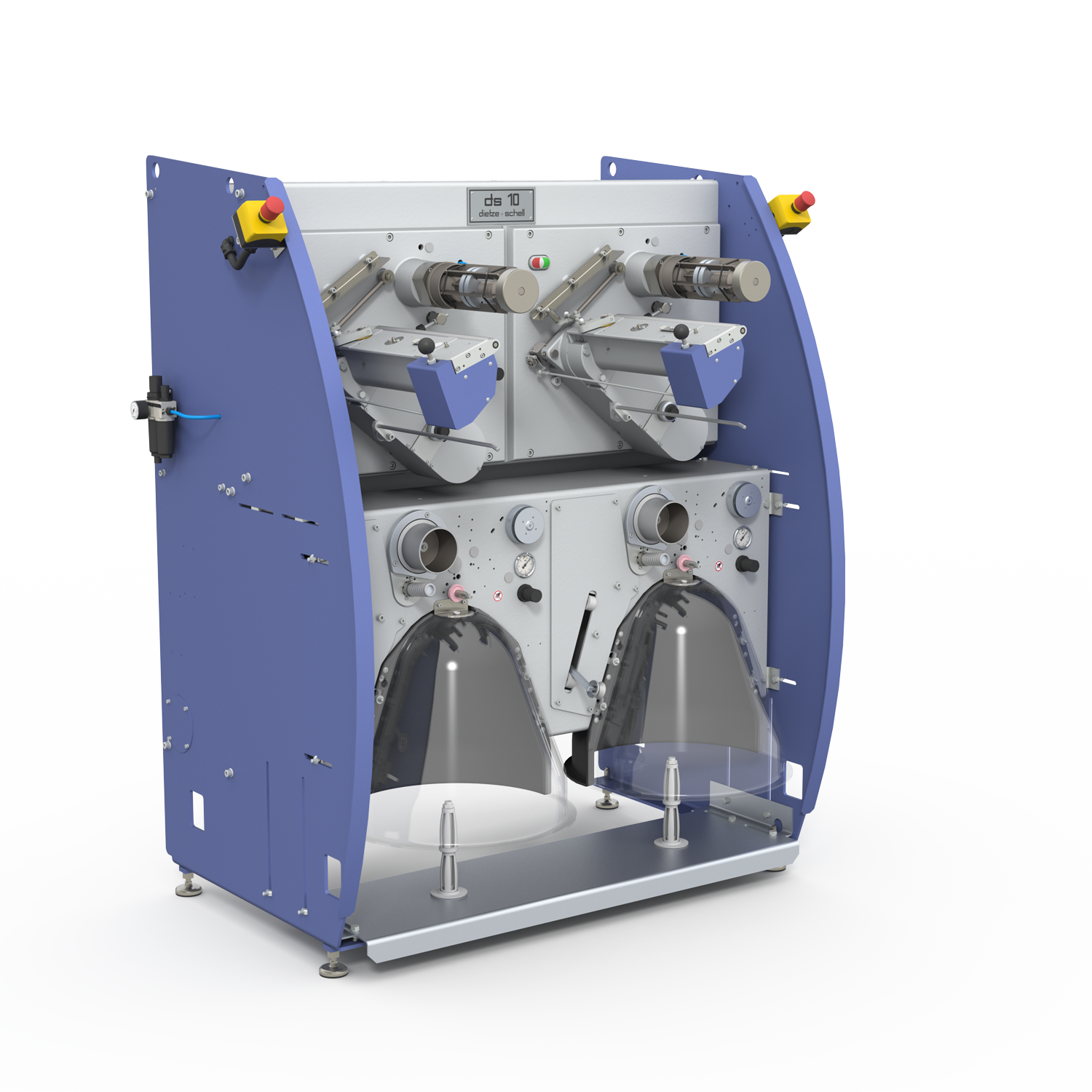

The Precision Cross Winder DS 10E has an electronic control. It was developed for companies subject to constantly varying requirements to the winding process. This applies in particular to contracted rewinders that need to adjust to the individual customer product requirements at short intervals. Manufacturers with a broad product range also benefit from the diverse options.

The machine electronically adjusts its winding width, thread tension, contact pressure, speed and other parameters. Being able to choose between dancer control and scissor brake is a special feature. The user can make this change without help.

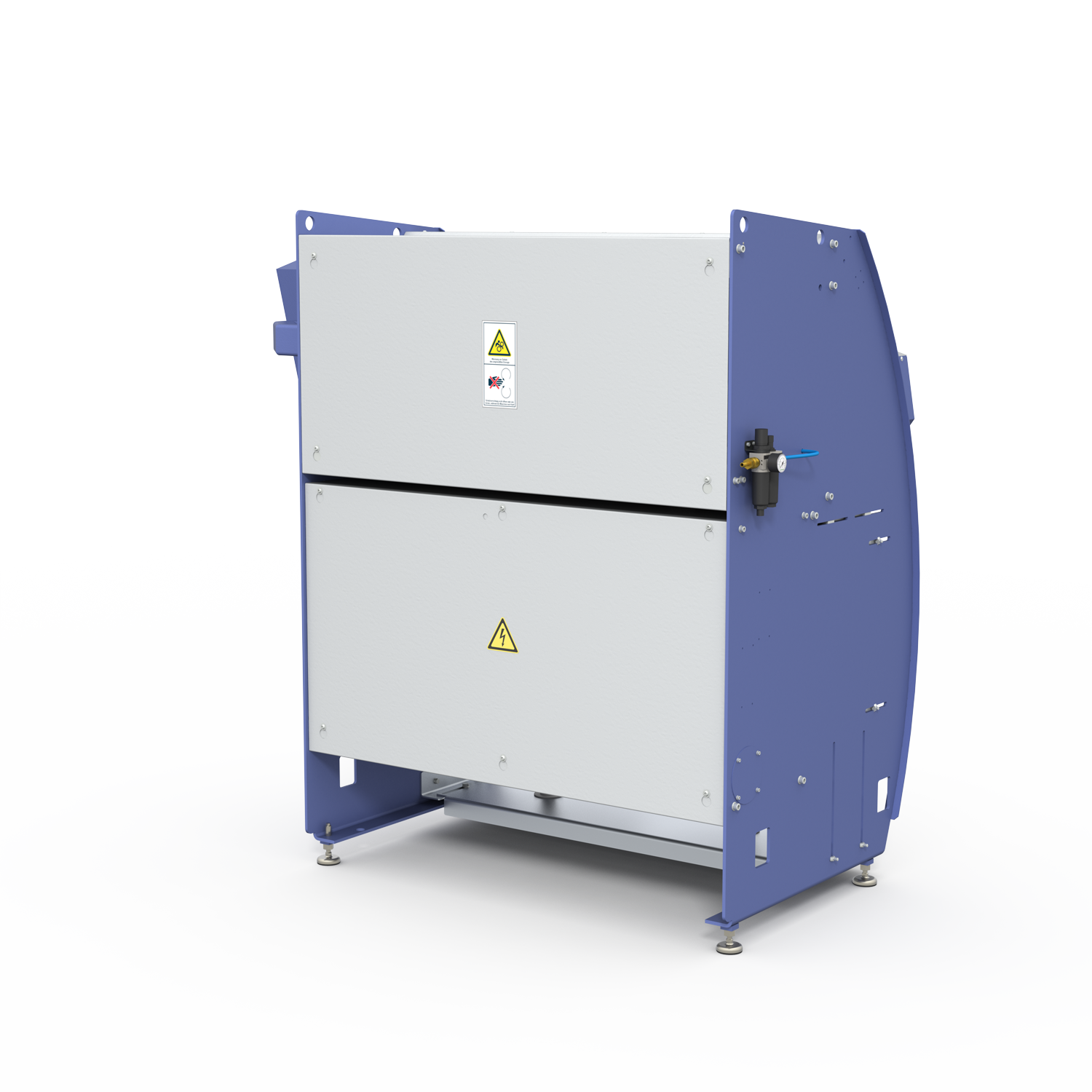

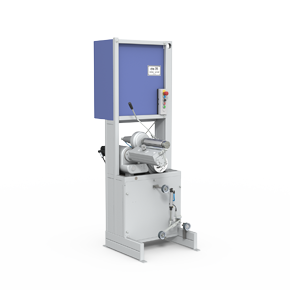

Robust mechanical design for continuous operation

The mechanical version, the DS 10M, has no electronic control for the crossing. This reduces costs. The setting is made via change gears. Bicon equipment is possible as well. This permits increase or decrease of the package width by up to 25 millimetres during the winding process. This type of machine is mainly used where the lines rewind the same product for months and changes are rare.

Dietze+Schell also offers the DS 10E and DS 10M as take-up versions for winding of continuously delivered threads or yarns.